ABOUT OUR PRESENCE IN INDUSTRIES

We believe in Commitment, Innovation and Quality!

Stainless Steel Pressure Vessel

Our Small pressure vessels are used to store fluids for a short period at different pressures and temperatures.

Agitator Vessel

We stand for the extreme level of development & manufacturing expertise in the field of Tanks & Agitator Vessel Technologies.

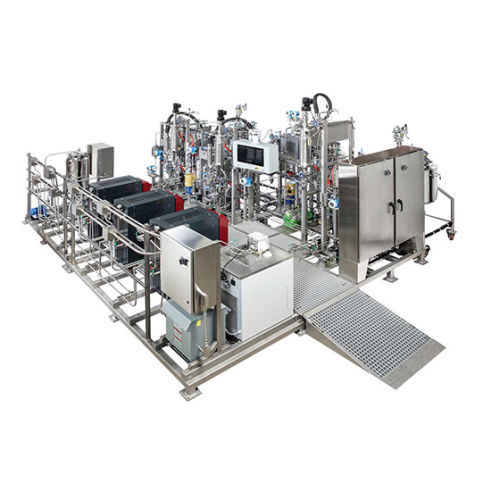

Automated Spray Solutions

We can provide complete Automation for spray application Coating, Cleaning, Washing & Humidification with different liquids.

Dust Control System

Dust is the major issue for worker safety & environmental impact for Industry, Dust become airborne by dumbing, grinding, agitation, etc ..